Adaptable Cooking Appliance: Nestling Inductive Cooking

3rd Year studio, major project

fall semester 2017

Background

The major 3rd year studio project tasked students to design a cooking product that enables at least two diverse cooking practices. Primary considerations were adaptability, repairability, and modularity. The assignment required iterative prototyping and user testing as key elements of the design process.

Context

Humans have been cooking for millennia, and did so solely with fire until the last hundred years when electricity was brought into cooking practice—providing both safety and convenience to the home cook. However, electricity-based cooking is not always the best method, heat is supplied two-dimensionally, while a flame supplies heat three-dimensionally, affording perfect conformation to the cooking vessel surface. This allows for even and efficient heat distribution on implements like woks which, are hemispheric and conventionally and more efficiently utilized over flame.

Ideation

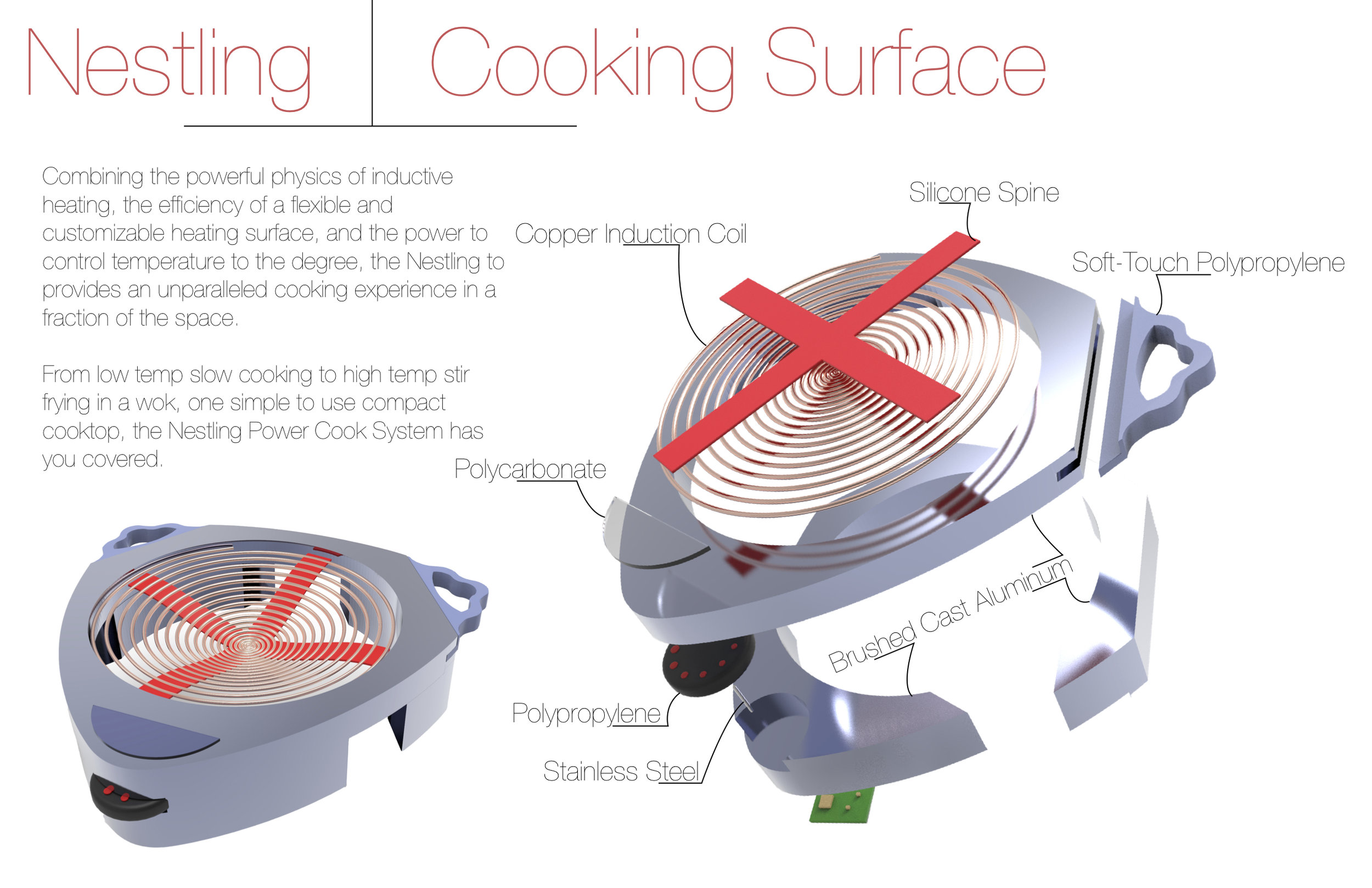

Ultimately, I sought to create a cooking product which supplies the power and three-dimensional heat distribution of fire, with the safety and sustainability of electricity. The central concept of the Nestling heating surface utilizes an electric heating coil that is flexible, conforming to any cooking vessel. This allows the user to complete many cooking tasks with greater efficiency, convenience, and improved performance. It does this safely through the inductive heating of a coil embedded in silicone.

Initial Prototyping

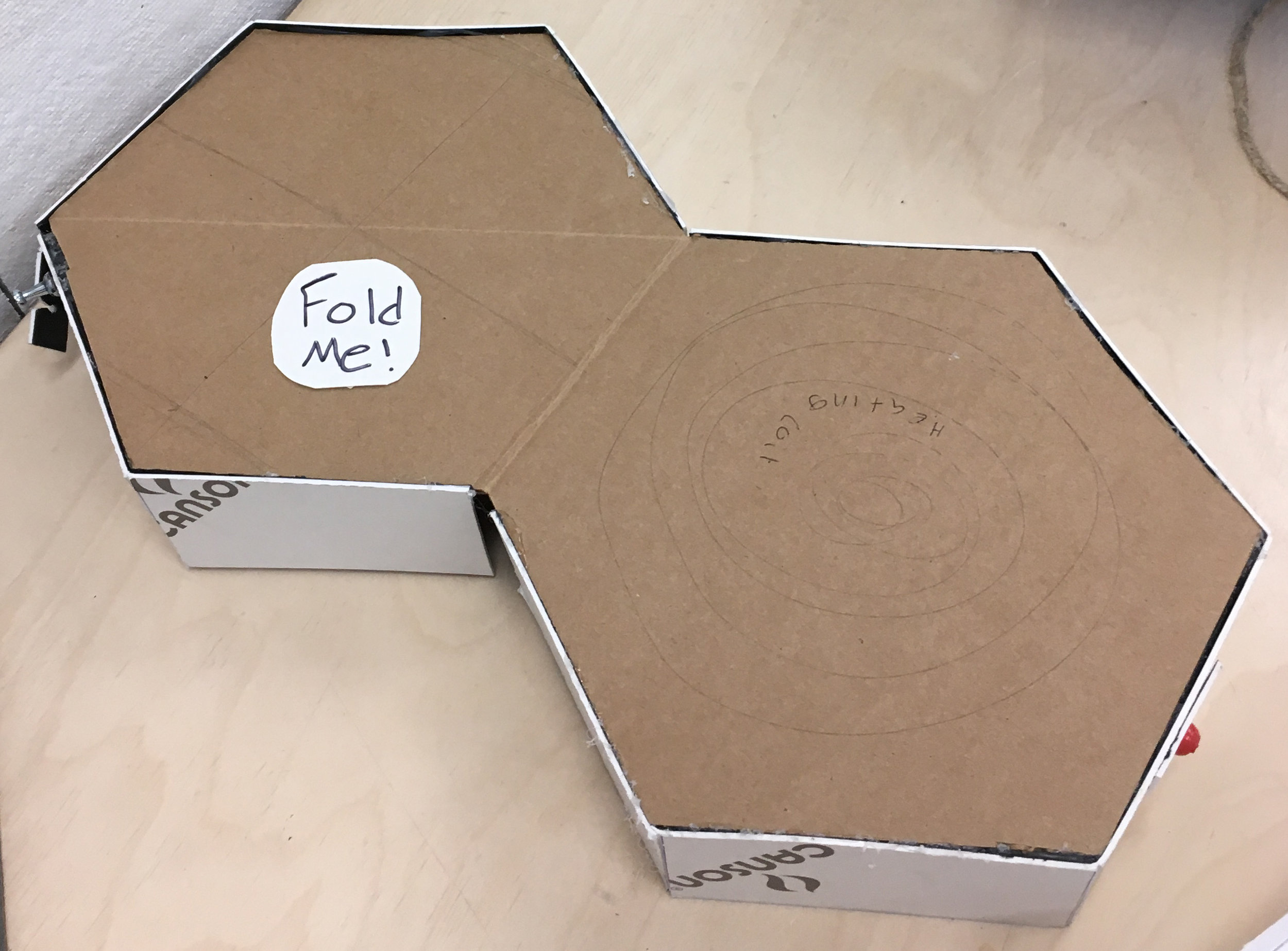

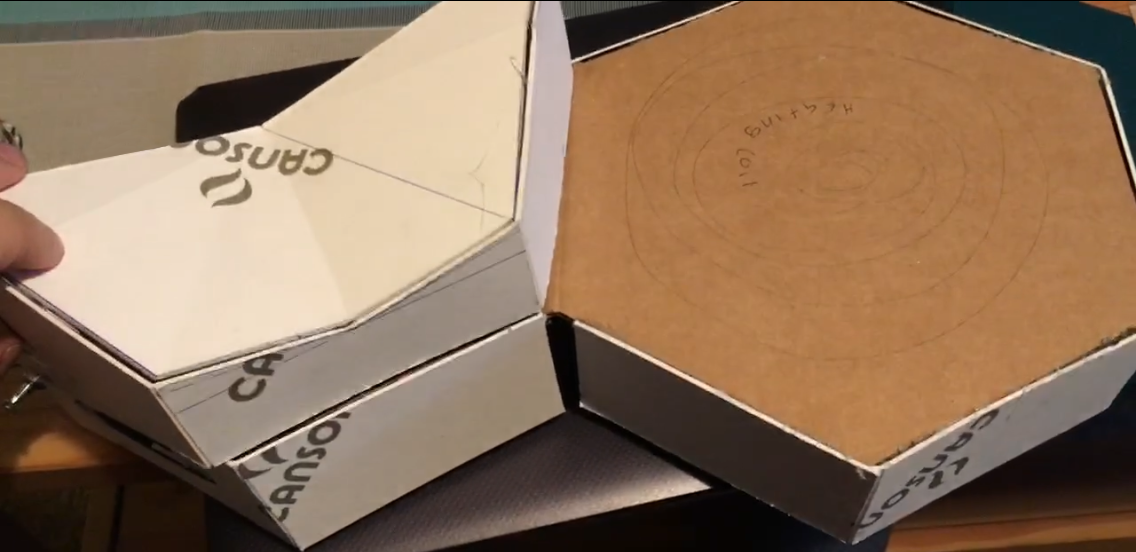

My initial concept was based on the conventional sandwich press—a multi-folding cooking surface with two independent heating surfaces allowing different foods to be cooked when the product is opened.

I was inspired by the shape and efficiency of a honeycomb—it utilizes materials and space efficiently as the hexagonal shape uses the least amount of material to fill a given volume, and the cells nest together easily to increase strength.

Problems with this concept— safety, the user could easily burn themselves; limited, designed to accomplish two specific tasks—grilling and pressing food.

Continued Prototyping

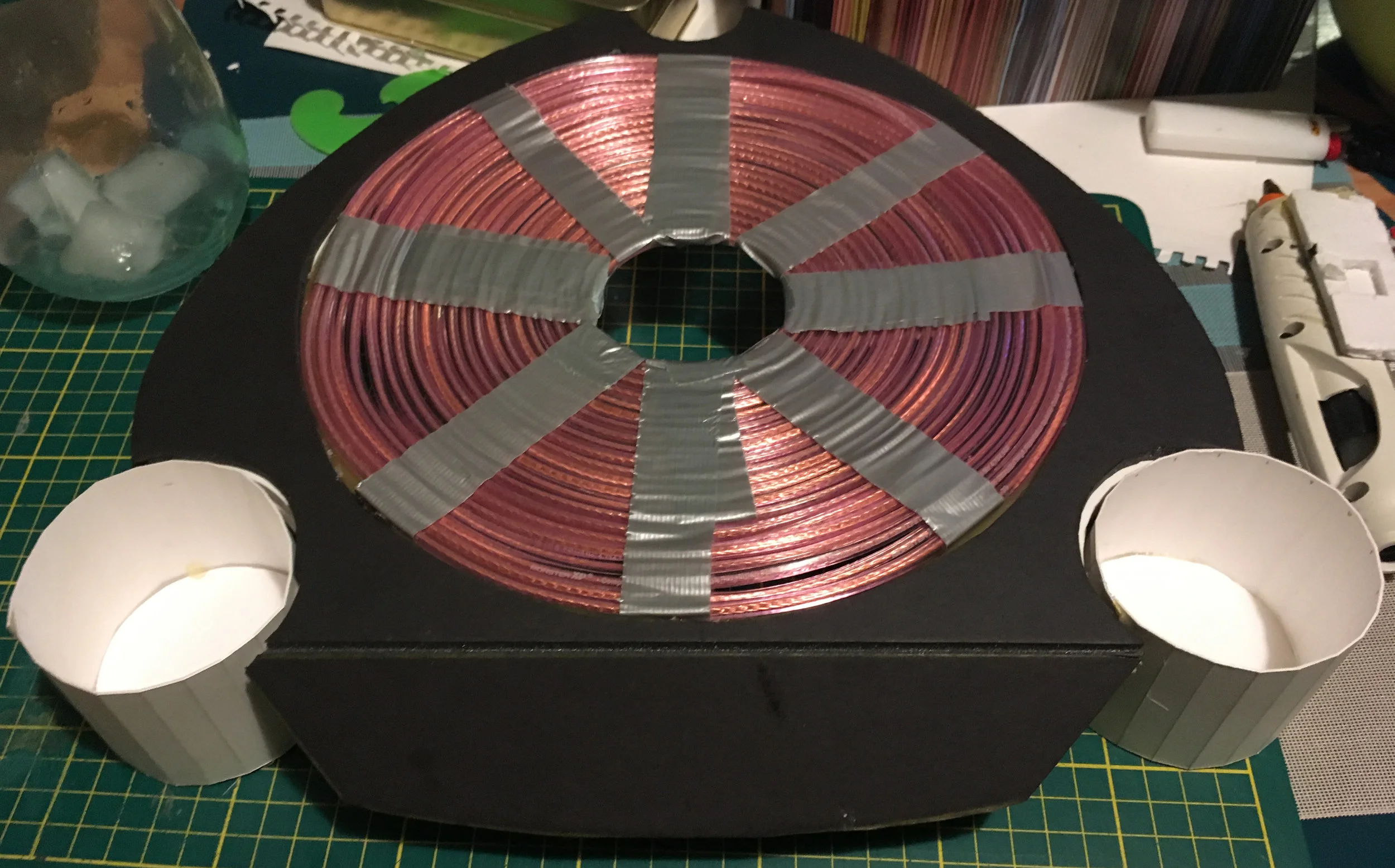

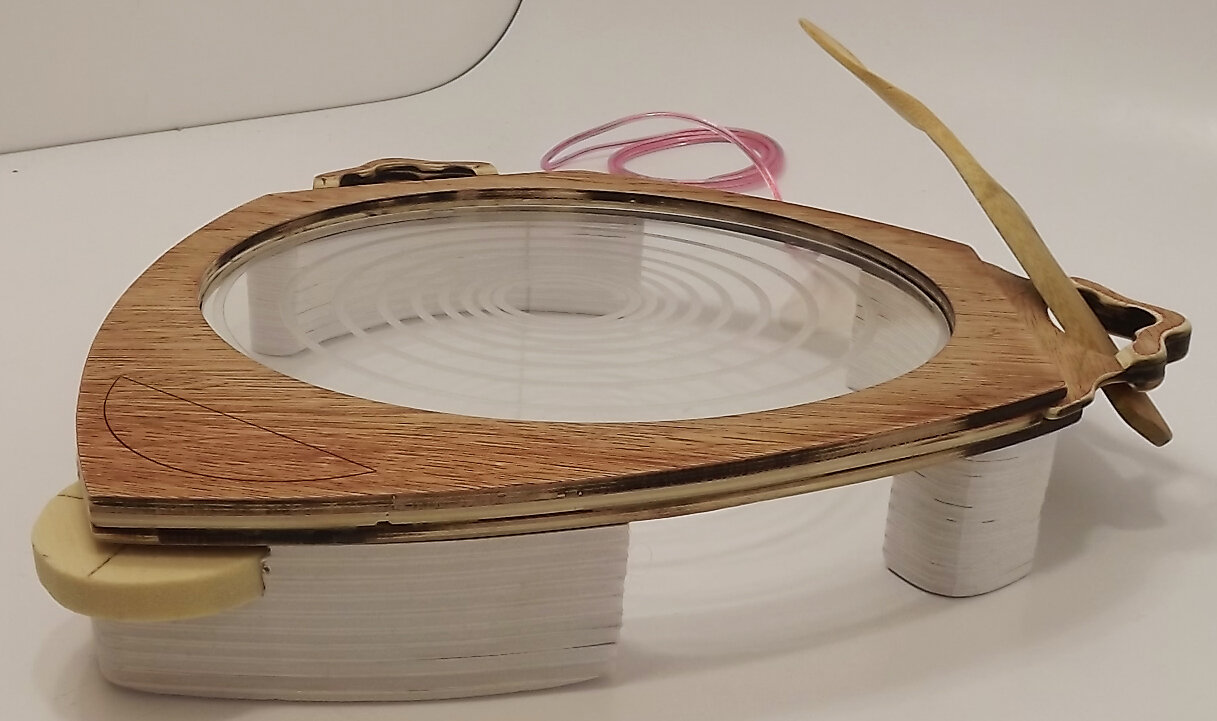

Next, prototyping tested an open concept allowing the user to perform any cooking task. This concept had a slack induction coil, which could accommodate any shape cookware (wok, pan, pot, etc.) and heat it efficiently.

Inspired by a previous project I had completed, Princess Margaret, I opted to use an inductive cooktop which is rapid, safe, and easy to use. Inductive heating is also more efficient than resistive heating at bringing surfaces to temp, and safer than gas/fire cooking.

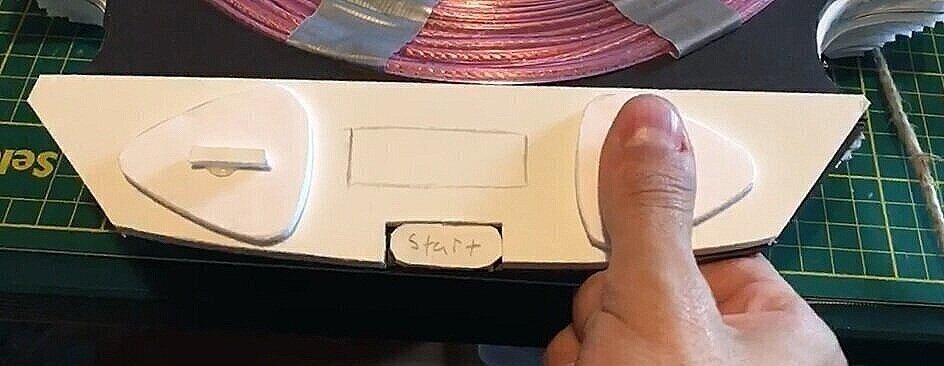

I developed a sliding control mechanism that allows variable heat control on the fly with the precision of a pinch grip.

Further Prototyping

Reevaluating the the shape of my product and what that shape communicates to the user—the hexagonal shape, initially invoked for its efficiency, could have a detrimental effect on the intuitive user experience I sought to create because it didn’t have a clear orientation. Where there is a circular shape in the center, I adapted the outer silhouette from a Reuleaux triangle to mirror and extend that visual aspect and reasoned that a triangular shape was easier to orient than a hexagonal shape.

The coil itself would be removable and embedded in silicone to make it easy to clean and dishwasher-safe. Pivoting the concept, my product would now stir-fry and slow cook. I added cups that could be used for measuring/cooking liquids and spoon rests.

Pictured below are the two control schemes I used for user testing.

User Testing

User testing generated a great deal of useful feedback. Both testers liked the slider temperature control; one tester offered that the button option felt juvenile. Combining analog control with digital feedback to increase precision, a dial control with a digital readout seemed an ideal solution to this feedback. They both felt the controls location was too tight should there be a large pan or wok in place. Repositioning the coil to the center provided more room on each corner for controls, this necessitated a move from a horizontal slider to a radial dial. Lastly, It was felt that most people would already have measuring cups or cookware and these, although helpful, were unnecessary.

Final Prototype

Though there was unanimity between testers and the studio professor that the measuring cups were not needed, I had aimed for the cups to be used as spoon rests as well, but because of their design, they were never intuitively viewed as such. Stepping back from the cup idea, I designed handles to serve two purposes: to rest utensils, and to grab the cord for wrapping; they are also removable to decrease footprint upon storage.

For more information regarding the design process check out my report:

Final presentation boards are below.